|

|

|

Item # APSS, CNC Punch-Shearing Combined FMS

|

|

|

|

|

The JFY APSS punch/shear combination tool is designed for unmanned operation with single and multicolumn warehouse towers. The unit enhances processing accuracy, reduces logistic time and improves material utilization. Programming software creates automatic processing procedures for material cutting, route optimization and tool management.

The APSS CNC punch-shearing combined FMS is an integrated plate processing equipment combining computer control technology, micro-electronic technology, remote monitoring technology and precision manufacturing technology. By combining the CNC punching machine and right angle shear. The position and processing accuracy is greatly enhanced and logistic time is reduces while the material utilization rate is improved. The combination of cubic warehouse and automatic loading and unloading system can reduce the work load, and improve the work efficiency and equipment up time. The internationally advanced automatic programming software can transform the graphic files into the processing procedures for automatic cutting of materials, automatic optimization of processing routes and automatic management of Tools. This equipment consists of cubic warehouse, loading robot, high-speed CNC turret punch machine, CNC right angel shear, sorting device and controlling system. The machine features with high flexibility, adaptable to different products. Whether it is a small lot with a variety of products, or it is large batch production, the customer's requirement can be easily met.

|

|

|

|

|

|

|

|

|

|

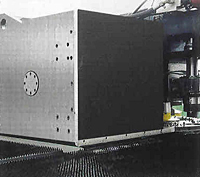

Cubic Warehouse

|

|

8 columns, each loading weight of which is 3000kg; the maximum processing plate is 1250 x 2500mm. The column at the bottom, owning more room, can be used as the loading table. The loading robot as well as high-accurate thickness measurement equipment and larger image |

|

|

Loading Device

|

|

It consists of loading robot, separating mechanism, thickness measurement equipment and vertical & horizontal move mechanism. On one hand, the plate from warehouse can be transmitted to punch machine, on the other hand, each piece of plate from the whole larger image |

|

|

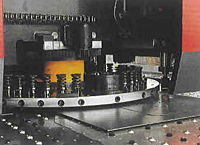

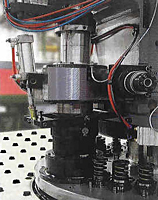

Punch Machine

|

|

O-type body with good rigidity and little deformation. Hydraulic drive. The speed can reach 1000 times per minutes. It has 24 stations, 2 auto-index, the max. traversing speed of plate is 110 m/min and the feeding stroke for once is 2500 x 1500mm. It is e larger image |

|

|

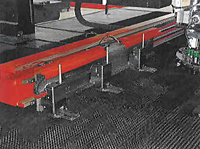

Right Angle Shear

|

|

The shearing mode is guillotine shear with little deformation. The double-side, synchronize, automatic mechanism is installed to meet the requirement of different plate thickness. High precision guideway guides the shearing slide block of the right angle larger image |

|

|

Intelligent Clamp

|

|

Three -intelligent clamps can automatically move their positions based on the plate requirement without the hands help to eliminate processing dead zone. They can float together with the plate. It also alarms when the plate comes off. larger image |

|

|

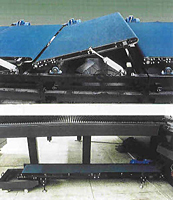

Sorting Device

|

|

According to the type, the sorting equipment functions to sort out the parts sheared by right angle shear and transfer them to the part boxes or discharge the waste. larger image |

|

|

Hydraulic System

|

|

The hydraulic system has a high speed, high efficiency and with very reliable characteristics. It makes the stroke variable, dropping quickly and slow punching and full speed return, which ensures the processing quality and improves the working efficiency larger image |

|

|

High Precision Ballscrew and Guideway

|

|

The large lead ballscrew and linear guideway from Germany or Japan are used to ensure processing accuracy. larger image |

|

|

Unique Turret

|

|

The turret adopts the specialized fixture for pair processing, ensuring the coaxially of the punches and dies, which can extend their service lives greatly; the inlay structure simplifies the structure of the turret, which also helps to extend its service larger image |

|

|

Unique Auto-Index

|

|

The auto-index adopts high precision wormwheel and worm mechanism. The auto-index can be expanded to 4 or 5 and the maximum die diameter can reach 88 9mm. larger image |

|

|

Concentrated Lubricating Mechanism

|

|

The concentrated lubricating mechanism can lubricate the various points directly to reduce work load and pair friction, improving its service life. larger image |

|

|

Central Control System

|

|

Adopts FANUC controlling system of the advanced level internationally, controlling the whole line (controlling units of the body and warehouse). The cubic warehouse can be controlled by PLC separately. Features with friendly operating interface and conven larger image |

|

|

Auto-Program Software

|

|

Friendly interface. Features with tool governing, automatic nesting, tool changing, repositioning, clamp intelligent evasion, automatic micro -connection setting, and routes optimizing. The CNC processing program can be produced automatically through CAD larger image |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|